(Continued from Accident 1)

Fireworks manufacturing plant

Causes

Based on the information collected by the inspection committee, it is assumed that the fireworks transfer operation was the trigger of the sequence of explosions. Ignition presumably occurred during the handling of the explosives.

Important findings

• The investigation revealed that primed explosive products, i.e., those products capable of setting off the explosive mixture contained in the cartridge if simply subjected to mechanical action (impact, etc.),

were found in the factory yard in front of the factory entrance and in the tool shed used as a garage for vans. However, under the regulations, fuses must never be inserted at an establishment of this kind, but are to be fitted only directly at the venue of a fireworks display.

• Lack of information and training provided to operators who, as experts in the field may be deemed to be well aware of the dangers of

handling primed materials; it suggests, rather, an excessive level of ‘confidence’ gained over time and perhaps overfamiliarity with work involving materials that in fact entail a high level of intrinsic risk.

• It was a general practice to store explosive materials that were subject to legal custody after being confiscated by the police, for indefinite period until they were past their expiry, in the sheds with explosive products manufactured by the company. Also, the quantity of these explosives exceeded the amount that was permitted by the authorities, not to mention the fact that their explosive classification was not identified.

• Furthermore, the inadequacy of the separation distances inside and outside the factory was discovered by government inspectors following the accident.

Lessons learned

• Operating procedures deployed by the company were unsafe and prohibited by the regulations, given the fact that primed explosive products were found in the factory, that were unlawfully fitted with electric fuses. Failure to comply with the operational safety procedures and conform to national regulations is a clear sign of negligence. Conformance with norms and standards for handling explosives should be an ongoing subject of audits, inspections and training on explosives production and storage sites.

• Stressful working conditions and pressure to complete jobs in a hurry can lead to violation of operational procedures and create hazardous situations. Dangerous processes require a stable time frame for handling the dangerous processes properly and time schedules to delivery should be planned accordingly.

• Operators need to maintain a culture of constant vigilance and prevent any complacency in handling of explosive substances. Typical strategies often include strict enforcement of safety procedures every hour every day, building awareness of accident potential through posting of near misses and accident lessons learned (from onsite or elsewhere), and frequent safety meetings where near misses or incidents of safe and unsafe behavior can be discussed.

[EMARS Accident #939, ARIA No. 46088. Similar accidents: EMARS Accident #816; ARIA: No. 28480 and No. 22018. See also Enschede at ARIA No. 17730]

|

Accident 2

Production of hunting ammunition

2 accidents at the same site

Sequence of events

A fire broke out on a pyrotechnic waste burning zone on a day when the production facility was closed for summer holidays. A single entrance provided access to this zone, partially enclosed by a barricade and protected by a fire hydrant. Pyrotechnic waste required a preliminary authorisation issued by the Safety & Environment (SE) unit. To be destroyed by burning, these waste materials needed to be laid out linearly along the foot of the excavation and typically on wood (i.e. pallets). The onsite presence of an equipped first response truck was mandatory whenever large quantities were being burned. During the morning hours and cognizant of the extreme instability of the wastes present on site, the SE unit manager was assisting two production technicians with set-up duties, since his two SE employees were absent from work, in proceeding with the scheduled elimination of these unburned materials. The task included raking and spreading the pyrotechnic waste onto pallets to facilitate drying. At the beginning of the afternoon, the onsite team distributed pallets over the layers of waste in two runs. Around 3 p.m., a spon-taneous fire ignited near the position of the SE manager, who was trapped by the flames and smoke. The other two crew members were able to escape from the zone unhurt. The SE manager, who happened to be standing 30 m from where the fire sparked at the foot of the embankment, died from his injuries in less than an hour.

Causes

The fire may have been triggered by friction of the powder which was dry and polluted, hence more sensitive, due to a pallet falling or skidding or the foot movement of the deceased manager.

Important findings

• The technicians who completed the work were regular workers and were not authorised or trained to work in the burning zone. The two, qualified and authorised SE technicians were absent from work, without replacement.

• The work was started without the presence of the first response truck which was mandatory.

• A stressful working environment was created by the manager having ordered completion of as much work as possible, given the instability of the waste stored onsite.

Lessons learned

In the above case, at least two critical safeguards for the process in question were ignored:

• Untrained workers were involved in dangerous activity for which they had no training and the requirement for the presence of the first response truck was ignored.

• Although it appears that specific authorization was required for this work, it appears that the authorization was given without actually meeting the safety criteria of the authorization.

Nonstandard procedures, i.e., procedures conducted outside normal operations, are particularly vulnerable to ad hoc management. Risks can be further reduced if the procedure has a checklist and requires authorization. These checklists and authorization procedures are vital to controlling risk and should be rigorously respected.

|

(Continued from Accident 2)

Production of hunting ammunition

In addition, it is possible that the particular dangers associated with pyrotechnic wastes were underestimated. Properties of pyrotechnicwastes are not defined because their composition varies considerably. Nonetheless, they are generally found to be more sensitive than classified substances from which they have been derived. Moreover, the treatment and disposal of these wastes relies heavily on the judgment, qualifications and experience of the technicians responsible for the job. Therefore, the operator should include waste treatment and disposal in the site risk assessment and maintain an acute awareness among employees of the potential risks of every associated operation. Moreover, the operator should have documented evidence that employees and contractors performing the treatment and disposal work have the necessary qualifications and experience for the job.

[ARIA No. 32086 with similar accident at the same site ARIA No. 45545. See also http://www.sozogaku.com/fkd/en/cfen/CC1000110. html; EMARS Accident #842]

Accident 3

Production and storage of explosives

Sequence of events

A fire broke out in the final assembly building generating a series of explosions seriously damaging the building and a specific part of the area. The problem occurred while closing the transport containers of the mortar rounds. The mortar rounds are transported in plastic containers that hold three mortar rounds in separate tubes. The operator experienced difficulties in loading the round into the containers and closing the container caps. Therefore, a gap remained between the container and the cap. The operator found that striking the retaining cap of the container with a mallet was enough to align it and to allow the cap to be locked in position.

Causes

The incident was caused by the ignition of an 81mm HE M512A1 mortar round during the final packing operation. One side of the pallet assembly was filled with 54 projectiles of 81mm. The primary cause was that the operator struck the retaining cap of the container with a mallet to align it and to allow the cap to be locked in position.

Important findings

• The neoprene liners of the container caps were substantially degraded so that the containers were difficult to close. In addition, the mortar round sometimes protruded from the plastic container making it more difficult to fit the retaining cap, to rotate it and to align it correctly.

• The technical cause was identified as ignition of the primer of the propulsion system of a mortar round by direct impact with the adjacent round during the mallet onto the anvil. It is probable that the operator directly but unintentionally hit the closing container cap operation and made the primer function.

|

• However, the investigation highlighted significant management system deficiencies that may have contributed to the accident. In particular, the employee training programme was cited as inadequate and there was evidence that management routinely tolerated unsafe behavior. Notably, the staff informed the management about the difficulty in closing containers but management did nothing in response to this information, allowing the unsafe practice to continue that eventually led to a serious accident.

Lessons learned

This accident is another illustration of a situation in which the operator flagrantly ignored both technical and safety management control measures that could have prevented an incident.

• Standard maintenance and control practices should avoid the presence of technical nonconformities of equipment critical to production and safety. Although the information from the investigation is limited, there was a clear pattern indicating that a specification or maintenance failure allowed degraded seals to remain in service.

• It is unthinkable that a quick fix could be considered remotely appropriate when dealing with explosive production and storage processes. If ad hoc procedures are invoked to compensate for a nonfunctioning process, it is a clear signal that production must be stopped to address the problem and identify safe options for proceeding. Note that if it is deemed that production can continue with a change of procedure, a management of change procedure should also be conducted to evaluate its impact on risk and confirm that it is a safe alternative.

• Major hazard sites are supposed to have functioning safety management systems. If management fails to respond to employee reports of technical problems on the production line, it is questionable that a management system exists, let alone a safety management system.

• In this case, despite their apparent lack of training, the employees behaved more responsibly than the management. The management’s choice to ignore employee feedback in this situation could substantially aggravate the company’s legal difficulties should an accident occur.

[EMARS Accident #887]

Accident 4

Propellant powder sieving

Sequence of events

The accident occurred in a building where propellant powders for ammunition are sieved. On the day of the accident two operators were assigned to the sieving plant, a young employee on a short-term contract, still in training, and an experienced operator in charge of training him. The operators’ first action was to dismantle and reassemble the sieving plant, as laid down in the operating procedure, with a view to cleaning it before starting the actual sieving of the powder. At around 4 a.m., a malfunction occurred in the sieving plant and a fire broke out in the machine spreading to all the powder stored in the sieving unit. The most experienced operator was in the room at that time. The alarm was set off and the ultrafast-response flooding and sprinkler systems were triggered.

(Continued in the endk of the webpage...)

|

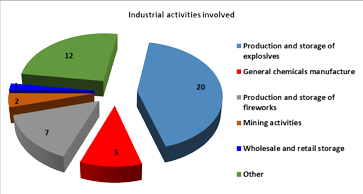

Statistics for explosives accidents

This issue of the Lessons Learned Bulletin offers insight into major accidents that occurred while manufacturing, storing or disposal of explosives. In preparing this bulletin, 62 accidents were studied, including 47 major accident reports in eMARS, 4 cases from the Japanese Failure Knowledge Database (http://www.sozogaku.com), 10 accident reports from the French ARIA database (http://www.aria.developpement-durable.gouv.fr/) and 1 accident was chosen from the U.S. Chemical Safety Board collection of investigations (www.csb.gov).

The most common types of accidents found in the study were those involving production and storage of explosives, at least 10 cases and explosive wastes or fireworks in 7 cases (e.g., EMARS Accidents #276, #729, #937, #939, #940), and 4 cases involving dismantling ammunition (e.g., EMARS Accidents #196, #551, #663 and #740). Further to these, 12 events were reported under category “Other” which includes explosives wastes or ammunition factories, too. In addition, the chart below presents the industrial activities associated with the eMARS accidents.

Accidents involving explosives are still occurring with a regular tendency, with to two to four events a year almost every year since 2000. In the last five years alone, there were twenty major accidents in Europe involving explosive substances1. Many of the events studied also appear to be repeat accidents, that is, the same accident occurred more than once within the same facility over a number of years (e.g., EMARS Accidents #729 and #1031; EMARS Accidents #276 and #918; ARIA No. 32086 and No. 45545). This recurrence is a strong indication that many sites are still failing to learn from past accidents.

______________________________________________________

1The majority of these events could not be used for this bulletin because they are still under investigation.

Figure 4: Number of major accidents involving explosives

(Source: eMARS)

|

Types of accidents involving explosive substances

In principle, explosives can be activated by a number of different types of energetic stimuli2. For production and storage accidents, the most relevant are:

• impact/friction

• fire/heat

• electrostatic discharge

• runaway reaction during explosives manufacture

In particular, the study highlighted the frequency of four different factors that significantly contributed to accidental occurrences involving explosives:

Unsafe behavior in handling explosives

Surprisingly many accidents appear to have underlying causes associated with poor safety awareness and behavior. On many sites where accidents occurred, the study found that violation of the most basic safety norms and technical requirements was the rule rather than the exception.

Internal transport of explosives

Internal transport of explosives on site appears to be a common activity associated with four accidents. This pattern suggests that often the elevated risk of impact to the transported explosive, created by potential collision, unstable terrain, or mechanical failure of the transport vehicle, is not adequately addressed or perhaps even considered.

Inadequate separation distances

Inadequate separation distances between storage facilities or production installations caused an escalation of the accident, causing propagation of explosions and subsequent fires due to the flying debris from one location to another in six cases.

Solidification of explosive matter in the reactor

In two cases, explosive material remained in the reactor and solidified, blocking the pot or the connected pipes, causing runaway reaction during process or startup operations that can elevate risk in more than one aspect.

___________________________________________________________

2Safety Report Assessment Guide: Explosives by UK HSE at

http://www.hse.gov.uk/Comah/sragexp/srag-explosives.pd

|

Inspection/audit questions

• How do you make sure that workers follow the internal rules and respect operating procedures in regard to explosives handling and operations and they do not violate these rules?

• Have all hazards and risks related to production or storage of explosives and fireworks been identified and analysed?

• What scenarios involving explosives substances have you considered in the site’s risk analysis? Has the potential for escalation/domino effect been addressed?

• How do the safety procedures address the possibility of an explosive substance being dropped?

• What evidence do you have that the company that disposes of the site’s explosive wastes has adequate knowledge on the characteristics of these substances/mixtures?

• What kind of active fire protection system is used in the storage buildings an production sites of explosives?

|

• Does the company have an internal emergency plan prepared and tested to respond effectively in case of an explosive incident?

• How are the quantities of explosives and fireworks stored and produced being monitored and tracked?

• Has your company ensured that adequate separation distances are maintained from all explosives storage buildings and production facilities and other buildings (and each other)? If so, how are the separation distances determined? If not, what measures have you in place to prevent a domino effect from one building to another?

• Have you recorded and reviewed past accidents and near misses?

• How do you ensure that explosives are not left outdoors for prolonged periods, accidentally or otherwise?

• What do you think would be the consequences of your worst case accident scenario? Are you aware that having such a devastating accident could cause you very serious damage, and your plant might never be rebuilt?

|

Accident 5

Explosives manufacturing factory

Sequence of events

Two massive explosions just seconds apart destroyed the Sierra Chemical Company’s Kean Canyon explosives manufacturing plant in Nevada, killing four workers and injuring six others. Because everyone was killed, the exact cause of the accident could not be determined.However, it is thought that on the day before the incident, leftover base material was left in the mixing pot by an operator but this information was apparently not communicated to the next shift. The next morning the worker returned, and may have assumed that the pot had been emptied. Without checking its contents, the worker turned on the motor to the agitator blades, setting off the initial explosion. This explosion occurred in a room where workers made “boosters” - small explosive devices used in the mining industry to detonate larger explosives. A second, more powerful blast destroyed a building used for drying explosives, leaving a 40-by-60-foot (12 m x 18 m) crater that was up to six feet (1.8 m) deep. The explosions had the force of a magnitude 2.0 earthquake and were felt some 20 miles (32 km) away from the plant. Sierra Chemical estimated that in all, 47,000 pounds (21 t) of explosives were consumed during the accident. The facility was never rebuilt.

Figures 2 and 3: Booster Room 2 before and after the explosion (CSB)

Causes

It is speculated that explosive material remained in a pot over night and due to the low outside temperature it solidified. The bottom of the mixer blade, which was embedded in the solidified explosives

|

in the pot, detonated the explosives by impact, shearing, or friction of the explosive material with the pot wall.

Another possibility is that chunks of explosive material were pinched between the mixer blade and the pot wall, causing the detonation.

Important findings

• Process Hazard Analysis (PHA) was conducted for Booster Room 1 applying the same process as Booster Room 2. However, no PHA was conducted for Booster Room 2. Furthermore, supervisors and workers were not involved in the hazard identification activities.

• The storage facilities and the two workshops were closer to each other than it is determined in the related guidelines, allowing propagation of explosion to occur. Also, it was found that building constructions were not compatible with the recommendations by the Department of Defense guidelines.

• The investigation uncovered evidence that both managers and workers were relatively unaware of the risks associated with the production process and fundamental norms of safe behavior and handling when working with these dangerous substances.

• Government inspections were conducted infrequently and inspectors generally did not have expertise in explosives manufacturing safety.

Lessons learned

• In this case, the operator appeared to underestimate or have become complacent about the serious risk of explosion inherent in production and storage processes involving explosives. For this reason, there were several warning signs that indicated that risks were not adequately controlled at the site.

• A process hazard analysis was only conducted on one activity. Process hazard analysis should be conducted for all dangerous activities on site. Moreover, workers were not involved in the hazard identification. Had they been, they may have pointed out additional dangerous activities that should be subject to the PHA.

• There were no written procedures and limited training, if any, on safe handling of explosives both in a general sense and specific to the processes on the site. As noted in the report, “Managers believed that, short of using a blasting cap, it was almost impossible to detonate the explosive materials they used or produced.” Widespread lack of awareness of the actual safety hazards on a major hazard site is a clear indication that risks are not being controlled adequately.

• There was little or no effort to ensure worker safety at all. While most of the workers were Spanish-speaking, even the standard government- required safety and health training was delivered mainly in English. There appeared to be no channels for workers to learn or speak about safety issues that concerned them.

• It is particularly important that high risk sites also employ appropriate technical measures to counter safety management system weaknesses. Appropriate separation distances between buildings are a standard technical measure to mitigate explosive risk. Having a protective building structure in place that complies with regulations could also prevent further injuries in case of an accident.

• A third barrier can be oversight of the competent authority, but also in this case, inspection authorities apparently were not adequately prepared or knowledgeable to recognise the unsafe conditions at the site.

[U.S. CSB recommendations at http://www.csb.gov. Similar accidents: http://www.sozogaku.com/fkd/en/cfen/CC1200041.html

and ARIA No. 24716]

|