Link to .pdf

Link to full MJV Good Practice Report "Vol. 5 - Chemical Hazards Risk Management in Industrial Parks and Domino Effect Establishments"

Link to Seveso Inspection Series Home Page

MJV Good Practice Report

Risk Management in Industrial Parks and Domino Effect Establishments

Industrial parks and domino effect sites pose particular challenges for risk management to prevent industrial accidents because they create a situation in which there may be more than one operator responsible for measures necessary to prevent or mitigate consequences of a potential accident. Industrial sites that were once unified under one operator’s management are now often divided into several companies according to different production and service activities. In this situation several separate organisations may be now working on the same site and share responsibility for certain prevention or mitigation measures. As one example, companies on the site may have made a common arrangement by agreement to outsource maintenance, internal emergency or other key site services. Hence, this situation and others like them raise the question as to who is taking full responsibility, both legally and practically, for ensuring that all necessary measures have been taken within these services to prevent and mitigate the effects of major accidents.

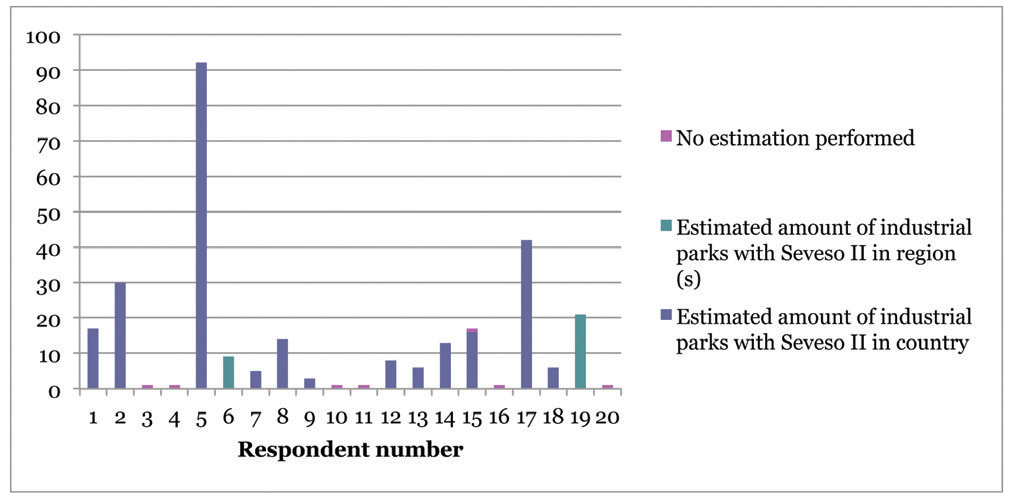

Figure 1: Number of industrial parks with Seveso II establishments (TWG 2 Survey-2008)

This Seveso Inspection Series short report is a summary of a Seveso Inspection Series expert report of the same name. The full report can be found at http://ipsc.jrc.ec.europa.eu/index.php/Publications/125/0/

A parallel circumstance exists in domino effect Seveso sites that are not necessarily in an industrial park with shared services. A domino effect is the cumulative effect produced when one event sets off a chain of similar events elsewhere. In other words the operations and services for each establishment are completely separate but an interdependency exists on the basis of an accident scenario. According to this scenario, the accident that may start on one site and include consequences causing a major accident on another site in the vicinity. An example of such an accident could be an explosion at one establishment that results in a projectile piercing a tank holding a dangerous substance on a nearby site. Similar to industrial parks, responsibility for preparing for and mitigating the consequences of such an event are not solely under the control of one operators.

Most EU and EEA countries1 have a number of Seveso II establishments located in large industrial complexes (indus trial parks, chemical parks) as well as areas where there is a high density of industrial operators creating a potential risk for domino effects (for example, port areas). When perform ing inspections in these Seveso establishments, inspectors are faced with challenges uniquely due to the proximity of neighbouring companies (both Seveso and nonSeveso es tablishments). In particular it becomes a significant chal lenge for inspectors to obtain assurance that “all necessary measures” have been taken on each site to prevent accidents and limit their consequences, as required by the Directive.

1 Countries of the European Economic Area (EEA) are obliged to adopt all EU legislation related to the single market, except laws on agriculture and fisheries. For the purposes of this document the «Seveso countries» are considered to include the 27 EU Member States, Norway and Iceland as EEA countries, and Croatia, an EU Candidate Country.

For this reason this project on chemical risk management in industrial parks and domino effects establishments was undertaken by the EU Technical Working Group on Seveso Inspections(TWG 2) to help countries learn from each other about their common challenges and to exchange on information on practices that could be considered effective for managing risk and enforcing Seveso compliance in industrial park and domino effect sites. Norway volunteered to lead the study of this topic which was identified as a prior ity by the TWG 2 in recent years. Norway first undertook a survey of the TWG 2’s inspectorate representatives (one per EU/EEA country) to confirm and clarify common challenges in the Seveso countries with implementation of Seveso in these two related areas. On the basis of the survey results, Norway propose to host a workshop on specific points highlighted in the findings within the framework of the EU’s Mu tual Joint Visit Programme for Seveso Inspections. A second survey was conducted of workshop participants, consisting mainly of Seveso inspectors, to obtain additional information about their experiences in enforcing Seveso compliance on Seveso sites associated with industrial parks and domino effects.

The Mutual Joint Visit (MJV) workshop on Seveso inspec tions in industrial parks and domino effects was held on 18 to 20 November 2009 in Tönsberg, Norway. The MJV was hosted by the Norwegian Directorate for Civil Protection and Emergency Planning in Tönsberg and coorganised by the Major Accident Hazards Bureau of the European Commis sion’s Joint Research Centre (JRCMAHB). In total there were 30 participants to the MJV from 19 countries (including 1 EEA, 1 EFTA and 2 Candidate Countries) and industry not including the participants from the host country, Norway. Also, two representatives of the JRCMAHB were present.

The goal of the MJV was to:

- Discuss challenges and practices in EU/EEA countries.

- Exchange experiences regarding the handling of industrial parks and domino effects in EU/EEAcountries.

- Evaluate the need for establishing joint inspection check lists/question lists for

- Conclude best practices and common understandings in a best practices document in the Seveso Inspection

The workshop was based on the concept of small group discussions focused on various topics and subtopics within the theme of industrial parks and domino effects. To give the participants a common platform for further discussions, two plenary sessions also consisted of presentations to highlight accidents and experiences of inspectors that demonstrated typical concerns and challenges associated with this topic. The breakout themes were largely selected on the basis of responses of Seveso inspection authorities to two surveys conducted on the topic prior to the meeting. For group dis cussions, participants were given a number of questions to drive discussion on each topic / subtopic. A plenary session followed each breakout session and in this session each group presented the main points from their discussions. The topics and subtopics were as follows:

- Session 1: Legal issues and organisation of industrial parks.

- Session 2: Inspection practices and tools for inspections.

- Session 3: Practices regarding joi documentation from industrial parks and authorities’ cooperation.

The MJV led to the following general conclusions and recommendations about approaches regarding industrial parks and domino effects.

Number and types of industrial park and domino effect sites in Seveso implementing countries

Not surprisingly, survey responses showed that there are a large number of industrial parks in the EU and other Seveso implementing countries. Some parks consist only of Seveso sites, while others have a mixture of Seveso and nonSeveso sites. These numbers demonstrate how important it is to have an enforcement focus on industrial parks that allows a broad perspective inclusive of nonSeveso sites when necessary.

Using figures provided by 14 countries, 353 groups of establishments (282 in industrial parks) were identified as having the possibility of domino effects. These figures represent just about half of Seveso implementing countries, meaning that the number of Seveso domino effects sites within the EU and beyond could well exceed 400 (of which around 80% may be industrial parks).

Note that the survey responses indicate that not all countries have identified their domino establishments. This means that some Seveso authorities have work to do when it comes to identifying groups of establishments with a possibility of domino effects.

Figure 2

Figure 2

Accidents in industrial park and domino effect sites

The following accidents/incidents were described by the workshop participants:

- A near miss in Aarhus (Denmark) in 2008 in which there was a fire involving palm oil next to an uppertier establishment (it contained a storage of formalin and methanol).

- The explosion of an oxygen tank belonging to one Seveso company caused considerable damage to surrounding sites. The explosion was caused by a change in the material of the tank which did not resist the pressure swings as well as

- In 2001, there was an explosion in a fertilizer plant in an industrial park in Toulouse (France) in which a large amount of ammonium nitrate residue detonated, causing devastating effects at the site and beyond. 30 people were killed, thousands were hospitalised, and there was enormous material damage. Fortunately, no notable domino effects

- In 2006 a pool fire located in a pipe rack in the Priolo industrial area (Italy) involved pipelines under the control of different operators. In addition to several injuries and high visibility in the media, the accident eventually exhausted the capacity of the fire fighting water

- The major explosion at the Buncefield fuel storage termi nal in Hertfordshire (United Kingdom) in 2005 took place adjacent to an industrial park housing over 600 businesses. Of these 80 were either completely destroyed or were damaged to the point of being

- In 2008, a power failure in a Belgian refinery led to the collapse of the flare. Because of this collapse, little drops of hydrocarbons came out of the flare, and a hydrocar bon film was spread out in the surrounding area. One employee in a neighbouring site was sent to the hospital with respiratory problems. Two days later, an employee of a third site was seriously burnt on his arm by a (small) jet fire, while he was replacing a gas bottle of oxygen. The jet fire was caused by a hydrocarbon deposit on the gas bottle (probably coming from the refinery two days earlier), in combination with a little amount of the oxidizing oxygen that was still in the bottle.

Inspection practices and strategies

Several countries have invested time and effort on refining practices and a number of innovative ideas were shared across the project through surveys and the workshop. It is clear that few authorities perform inspections targeted at the overall safety level in the industrial park. The inspections are mainly performed at Seveso establishments located within the park and most countries inspect each Seveso operator in the same industrial park separately.

The following are specific practices that were shared by various countries:

Identification of the property and the management of some utilities, such as pipelines

This concerns utilities, for example, that go through the ar eas of different operators, is very critical. Therefore during the monitoring of industrial parks it is important to pay particular attention to the modality of the management of the interconnecting and the mutual utilities.

Requiring that a legal entity (person/company) be responsible for operating the industrial park

In addition, a few other countries relied on voluntary or mandatory provisions for establishing contracts or agree ments between sites on common services, such as emergency response.

Enforcing the establishments’ duty to exchange information

To fulfill this requirement, authorities made sure that near by operators were provided with information concerning a Seveso site (or sites) that could be the source of a domino effect on their sites. Furthermore, operators were asked to agree on procedures by which the reciprocal exchange of information should be performed.

Checklists for inspections

It is difficult to get a good picture of the safety situation in an industrial park since the establishments can be at differ ent levels in regard to Seveso and in regard to overall safety culture development, have different inspection authorities, etc. The checklists can aid in producing a more consistent evaluation.

Dialogue between the competent authorities and joint inspections in large industrial parks

In particular, authorities may get information about the risks of nonSeveso establishments by using environmen tal, work environmental and civil protection laws. The non Seveso establishments could, for example, be inspected by the environmental authorities.

Conducting inspections targeting the overall safety level in the industrial park

In some cases these inspections were somewhat routine and others and overall safety inspection was tied to spe cial situations or particular accidents, or reserved only for large industrial parks. In other countries the inspectors per formed an overall site safety check of the industrial park on one specific element. For example, inspectors would ob serve emergency plan test exercises or would check that adequate exchange of information had taken place between members of domino groups.

Evaluation of the possibility of domino effects of Seveso establishments on non Seveso establishments

In more than one country, the nonSeveso establishments were considered as external risk sources and are examined in the safety reports.

Figure 3

Figure 3

Requiring establishments within an industrial park to have a joint emergency plan

In addition, in one country domino ef fects for upper tier establishments are evaluated in the safety reports. In case of a joint safety report, the establish ments were considered as one entity regarding the domino effects. Another country explained that if the opera tors did not prefer to make analysis of domino effects together, they were all asked to make analysis of how their installations could impact neighbour ing installations, and then to compare their assessments.

Figure 4

Figure 4

Requiring different establishments within an industrial park to be involved in preparation of a joint analysis of domino effects

Another country indicated that a joint emergency plan was not mandatory but the local authority responsible for preparing an offsite emergency plan was expected to take account of po tential consequenc es of accidents at all establishments in close proximity and could choose to produce a generic plan for the entire industrial park. It was also noted that joint safety reports were allowed by some countries but in reality very few establishments have chosen this option.

Requiring establishments within an industrial park to have a joint emergency response organisation

In some cases it would depend on whether all establishments were under Seveso II or on the hazard potential of the site.

Legal instruments and definitions

Few countries have legal instruments that provide support to inspection and oversight of Seveso implementation in industrial parks. In the vast majority of the participating countries, there is not a legal definition of industrial parks; the legislation does not require that there be a legal entity responsible for operating the industrial park; and operators of Seveso sites are not legally required to make a contract with the operator of the industrial park regarding emergency related tasks.

In fact, only two countries could provide legal definitions of industrial parks. Several difficulties in creating a common definition were noted by workshop participants. Creating a definition of industrial parks that properly included all locations rel evant in nature to the true meaning of industrial parks and excluded those that were not relevant, proved to be a particular challenge. Moreover, though enforcement of the Directive can be particularly challenging in industrial parks, workshop participants general ly felt that specific legal definitions or other provisions in order to aid Seveso enforcement, are unnecessary. Most countries seem to be satisfied with existing regulations provided that the regulations can be adapted a more flexible way.

Inspection checklists and other tools

Many of the participating countries did not cite specific tools (guidelines, checklists, models, software) used for inspecting industrial parks and/ or assessing domino effects. Several of them use general checklists or question lists. However, the surveys provided a long list of questions in spectors could ask during inspections in industrial parks in addition to the “normal” Seveso inspection questions. These can be sorted into the following categories:

- communication and exchange of information between operators

- cooperation between operators

- personnel safety

- domino effects

- emergency planning

- infrastructure

As for the tools inspectors of industri al parks would like to have, the work shop participants listed:

- (better) checklists and guidelines

- joint international inspections with a learning process afterwards

- access to independent, competent management expertise

- the power to serve an order to pro duce an improvement plan

- an expert institute on analysing risk and consequence

Ongoing challenges in assuring compliance

Many countries still have questions about what strategies and techniques would be most effective in enforcing the Directive in industrial parks and for promoting prevention and emer gency preparation in regard to domino effects.

Most workshop participants indicated that they had limited ability to recog nise potential risks or enforce more appropriate protection measures associated with nonSeveso neigh bours. It was noted that risk based prioritisation of inspections focuses on Sevesoplants rather than on the neighbouring nonSeveso facilities. Even information exchange with non Seveso neighbours on potential risks is a challenge due to differences in technical knowledge and differences in business contexts and company culture.

The following challenges were high lighted:

- Maintaining adequate resources, knowledge and

- Lack of joint risk analysis and joint incident control plans for whole industrial parks, and support from the legislation to be able to de mand this. How to integrate dom ino effects in risk

- Communication and interaction: between the authorities and the establishments, between domino establishments, between Seveso and nonSeveso establishments, and the need to develop interven tion strategies that the authorities can use to promote a continuous and open exchange of information between

- Lack of criteria for identification of establishments which are obliged to exchange data due to their prox imity and possibility of domino ef fects.

- Different challenges regarding inspections:

- the need for guidelines or other inspection tools specific for industrial parks, and spe cifically for domino effects;

- achieving a more comprehensive and robust en forcement;

- how to combine Seveso and nonSeveso inspec tions;

- The change of site ownership from one owner to multiple owners and keeping track of changes in owner relation ships. This can cause changes in safety policy over time and significant risk of loss of knowledge and experience. In this situation an inspector often may not know whether previous findings still apply.

- Responsibility issues – both among the competent au thorities and the members of the industrial

- Employing more appropriate and effective measures to avoid

- Ensuring that risk is reduced to a level as low as reason ably practicable and that the establishments are more active on a common basis to really increase the safety situation at the

- Coordination of emergency organisation related to such establishments. Specifically, a need for joint fire brigades was indicated.

Figure 5

Figure 5

Questions to ask when inspecting industrial park or domino effect sites

Communication and exchange of information between operators

- What information is exchanged between operators, how is this done, what is the frequency of this contact, and is it formal ized? What routines are in place?

- Is the necessary information about risks being exchanged?

- Is there a periodic meeting where informa tion about changes in risks, emergency de vices, etc. can be shared?

- Are emergency plans being shared be tween operators?

- Questions about information exchange re garding domino effects

- What procedures have been established to facilitate communication and information exchange procedures in case of an emer gency?

Cooperation between operators

- How do the operators cooperate in the ar eas of risk analysis ? emergency response? alarms and control systems? fire brigades and equipment? organisation of rescue services?

- Are responsibilities between the establish ments clearly defined and if so, how are they defined?

- Have the operators themselves identified any unclear areas regarding shared re sponsibilities, and how have these been dealt with?

- How are common routines developed?

- How do the operators deal with the hiring of common personnel and subcontractors and their safety training?

- Are there any common procedures (e.g., per sonal safety practices, emergency response, etc.) for the companies?

- Are there common exercises and emer gency drills?

- Has a joint committee been established to oversee cooperation on shared responsibilities? What are its conclusions?

- Questions regarding joint risk evaluations and joint emergency preparedness.

Personnel safety

- Are there evacuation directions for person nel and vehicles?

- Do the employees have the correct emer gency clothing and devices for dealing with dangerous substances? How is this organ ised so they can get to them in case of an emergency?

- Other occupational safety and health re lated questions.

Identifying and establishing controls for domino effect sites

The authorities usually decide whether the potential for domino effects exists. Most authorities identify and moni tor potential domino effects establishments through the evaluation of safety reports, through site inspections, use of digital maps and notifications from the establishments. Evaluation of possible domino effects is either performed as part of the safety report assessment, or as a separate process. However, some countries have encountered estab lishments that do not always agree that they are domino establishments.

Most Seveso authorities have little control of the local per mission procedures leading to the location of new high risk establishments. This can result in new domino effect estab lishments, since consideration of possible domino effects is seldom addressed in landuse planning. The workshop par ticipants listed some proposals for approaches on how to reduce the possibility of domino effects:

- good landuse planning, also addressing domino effects

- incentives to stimulate relocation of the establishments

- strengthening lines of defence through addition of appro priate safety equipment, instrumentation,

- authorities request operators to revise their risk assess ment in order to identify risk reducing measures

Cooperation between establishments

Several countries require or recommend Seveso sites within an industrial park to share or coordinate certain risk man agement information, such as:

- safety reports

- safety management systems

- internal emergency plans

- risk assessment

- emergency communication systems

- industrial park emergency plans

- information about domino effects

The following topics were suggested as the highest priority for cooperation between Seveso and nonSeveso estab lishments for risk management:

- hazard identification

- risk assessment

- assessment of domino effects

- management of changes that affect shared risks

- emergency response planning

- process shutdowns

Approaches suggested for encouraging establishment co operation included:

- Extensive inspections from authorities combined with information and

- Checklists for use by both Seveso and nonSeveso establishments

- worked out in cooperation with

- Conferences or meetings where authorities and establishments

- meet and exchange information

- Asking companies to share safety reports and work towards making them more homogeneous

Common services in industrial parks that may be critical for safety

The most common gap noted for industrial parks in relation to safetycritical services appeared to be unclear account ability among establishments in regard to the maintenance and the running of common installations, equipment and property.

The common service elements considered to be most criti cal for risk management were:

- emergency preparedness and response

- utilities and their backup

- security and admission control

- safety critical maintenance

- infrastructure

- hazardous waste

- cooperation in health safety and environment matters

- information to contractors working at the site

Joint safety reports and emergency plans

In most countries, the individual operators make their own safety reports. However, in some countries, different prac tical approaches have been tried to allow and sometimes promote a joint report. However, the workshop confirmed that other countries do not encourage or accept joint safety reports. In any case, there are no laws that can force indus trial parks to make joint safety reports. The production of a joint safety report by establishments is generally voluntary in countries where such reports are accepted.

Most countries do not have specific legal requirements for joint emergency plans in industrial parks or for domino ef fects. However, many countries can enforce the establish ment of joint emergency planning, preparedness and re sponse in industrial parks on a case by case basis. In many countries, each establishment in an industrial park has its own emergency plan. Still many countries reported having a mix of individual and integrated emergency plans, with a clear majority of individual plans. In many countries, indus trial parks voluntarily develop joint emergency plans.

The highest priorities in inspecting an emergency plan of an industrial park were identified as follows:

- Clarity of roles and responsibilities;

- Consideration of the relevant scenarios and plans about how to attack different The actions to be taken first depend on the hazards and chemicals involved, and knowledge of the hazardous materials and the resources available is therefore crucial;

- First response: education and training of internal first re sponse personnel. A short first response time (5 minutes is being mentioned) is important in order to limit the con sequences until the external help arrives;

- Internal communication: The other establishments must have accurate information to make sure they know how to respond. A good communication and alarm system is fundamental;

- External communication: communication with the police, the health authorities, the fire brigade – and the public. Public relations: it is important to have a controlled rela tion to the media, with designated persons to communi cate with them.

Cooperation between authorities

Cooperation between authorities varies greatly between countries for industrial parks and domino effect establish ments. Some countries have no need for cooperation since they have one authority; others have many authorities and have established more or less formal ways to cooperate. A few countries have established joint Seveso inspection teams, and all Seveso inspections are performed as joint inspections.

Domino effects

- Have the risks of major accidents related to domino effects been identified?

- What measures have been taken to de crease the risks connected with domino effects?

- Are the industrial sites near the establish ment impacted by domino effects?

- What kind of activities are taking place in nearby sites? Are dangerous goods involved? If so, what accident scenarios have been foreseen? What information has been provided and when did the last information exchange take place?

Emergency planning

- Are there established procedures in case of a major accident?

- Is there periodic testing with the fire bri gades?

- Who communicates an emergency situa tion to neighbouring sites, what informa tion will be given, and how will this be done?

- Is there a shared alarm or fire control system? Who is responsible and how is it used?

- How do the operators contact one another and share information in case of an emer gency?

- How will the overall emergency response be coordinated?

- Are emergency plans being shared be tween operators?

- Ask for documentation about the testing of emergency services.

- How does the individual operator’s onsite plan and with the offsite emergency plan?

- How do operators cooperate in preparing and executing emergency drills and com mon training exercises?

Infrastructure

- Have the operators defined hazard control and maintenance responsibilities in regard to common infrastructure?

- What risks are associated with “intercon necting” features such as pipelines?

- Who is legally accountable for the safe management of pipelines?

- How is information on the status of com mon infrastructure (such as pipelines and utilities) communicated? What is the pro cedure for reporting and addressing prob lems?

- How is management of change addressed for common infrastructure?

General conclusion

Because of the potential total risk associated with the ag gregation and proximity of operations in industrial park or areas with potential domino effects, it is of great impor tance that responsibilities regarding safety and emergen cy preparedness are clearly defined, and that factors that could lead to the escalation of accidents between estab lishments are identified and properly dealt with in order to minimize eventual domino effects. Lack of clarity regarding collective risks and accompanying responsibilities of affect ed establishments (Seveso and nonSeveso alike) can result in certain accident risks being overlooked or inadequately addressed. While significant challenges remain in regard to managing risks and ensuring compliance associated with in dustrial parks and domino effect sites, a number of innova tive strategies have been employed by inspection authori ties to encourage cooperation between establishments and focus attention on elevated risks when dangerous establish ments are in close proximity to each other and other busi ness interests.

PDF Version for printing

Vol. 5 - Chemical Hazards Risk Management in Industrial Parks and Domino Effect Establishments

Short version(current report in pdf)

Go back to the Common Inspection Criteria website